The Ultimate RainierGPR Concrete Scanning Option Described

The Ultimate RainierGPR Concrete Scanning Option Described

Blog Article

Harness the Strategic Edge of Concrete Scanning for Unparalleled Project Success and Top Quality Assurance

In the world of modern construction and infrastructure development, the application of concrete scanning technology has actually arised as a critical tool for guaranteeing task success and maintaining high quality requirements. This innovative method offers a strategic side by offering essential insights into the architectural honesty of concrete elements, thus enabling educated decision-making throughout the project lifecycle. By delving into the midsts of concrete make-ups and uncovering surprise anomalies, stakeholders can proactively deal with potential dangers, improve operations, and optimize resource allotment. However, the real power of concrete scanning lies not just in its capability to enhance job outcomes yet likewise in its capability to change standard practices, establishing a new standard for accuracy and performance in the building sector.

The Value of Concrete Scanning

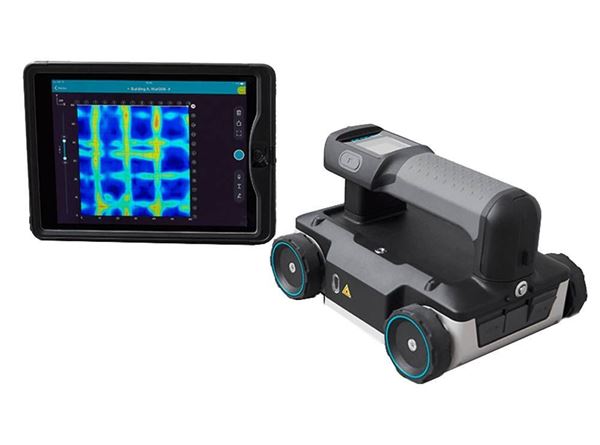

Concrete scanning is a vital action in building and construction tasks to ensure the safety and security and integrity of structures. By using different scanning modern technologies such as Ground Permeating Radar (GPR) and electromagnetic induction, construction groups can non-destructively review the subsurface of concrete structures to identify prospective risks like rebar, channels, or post-tension cable televisions. This details is critical for project managers, service providers, and designers to make enlightened choices and stay clear of pricey mistakes throughout the construction process.

Among the primary reasons that concrete scanning is so important is its capability to avoid mishaps and injuries on the construction website. Unintentionally reducing through a live electrical conduit or damaging post-tension cables can have catastrophic consequences, not only in regards to safety and security but additionally in regards to task hold-ups and financial effects. By carrying out detailed concrete scanning prior to any drilling, reducing, or coring activities, building and construction groups can reduce dangers and produce a much safer working environment for every person entailed.

In addition to safety factors to consider, concrete scanning likewise plays a key function in guaranteeing the long-term sturdiness and quality of the framework. By spotting any kind of abnormalities or flaws concealed below the surface area, such as spaces or delamination, early intervention can be implemented to resolve these issues prior to they escalate right into more substantial problems. Inevitably, purchasing concrete scanning is a proactive action that can save time, cash, and sources in the future, while additionally maintaining the highest requirements of building and construction quality.

Advanced Technology for Precise Outcomes

Furthermore, 3D scanning innovations provide a thorough view of the subsurface atmosphere by developing thorough electronic versions. These designs provide useful insights into the structural integrity of concrete elements and help in determining possible weaknesses before they escalate right into major problems. By integrating these advanced technologies right into concrete scanning practices, construction teams can enhance operations, decrease project hold-ups, and make certain the general quality and success of the task. The accuracy and performance used Go Here by these tools contribute dramatically to the task's success by promoting notified decision-making and improving quality control measures.

Enhancing Job Performance and Timelines

Moreover, concrete scanning enables groups to recognize prospective risks and structural read here weaknesses early on, enabling prompt remediation and preventing crashes that could thwart job timelines. The real-time information provided by scanning devices facilitates informed decision-making, leading to smoother sychronisation among various trades and stakeholders. This boosted partnership lessens problems, boosts efficiency, and eventually accelerates task delivery.

Furthermore, by proactively addressing issues via concrete scanning, building and construction groups can stick to timetables a lot more properly, minimize downtime, and enhance source allowance. The ability to detect surprise barriers and confirm architectural stability successfully adds to general project efficiency and timelines, making sure effective end results and customer contentment.

Ensuring Safety And Security and Threat Reduction

Risk reduction strategies can be improved through the in-depth information provided by concrete scanning, making it possible for project groups to make enlightened choices that lower the possibility of unexpected incidents. In addition, by accurately mapping out subsurface problems, service providers can prevent costly rework, delays, and damage to existing frameworks, additionally contributing to total project safety and security and success. Applying concrete scanning as a routine technique not only ensures a safer job atmosphere but additionally imparts confidence in stakeholders relating to the job's commitment to top quality and danger monitoring.

Quality Assurance Via Concrete Scanning

Concrete scanning plays a pivotal function in maintaining quality control requirements within building and construction tasks. By using innovative scanning technologies such as Ground Penetrating Radar (GPR) and Concrete X-ray, project managers and designers can make certain the honesty and quality of concrete structures. Via concrete scanning, potential problems, such as spaces, splits, or enhancing bar blockage, can be found non-destructively, permitting prompt treatments to keep the architectural honesty of the task.

Quality assurance through concrete scanning not only aids in recognizing existing issues however likewise makes it possible for aggressive measures to avoid future issues that could endanger the safety and security and long life of the framework. By carrying out detailed scans at crucial stages of construction, teams can validate the precision of architectural plans, verify the positioning of essential components, and attend to any kind of inconsistencies immediately. This aggressive strategy decreases rework, minimizes expensive delays, and ultimately leads to the shipment of high-quality, resilient structures that meet or exceed industry requirements.

Final Thought

In conclusion, concrete scanning plays an essential role in making certain task success, high quality, safety, and efficiency guarantee. By using sophisticated innovation for accurate outcomes, building jobs can be completed with greater accuracy and within timelines. The strategic edge given by concrete scanning enables positive threat reduction and enhances general job management. Incorporating concrete scanning right into building and construction procedures is vital for attaining exceptional success and making certain high quality outcomes - RainierGPR Concrete Scanning.

In the realm of modern construction and framework development, the application of concrete scanning innovation has arised as a critical device for guaranteeing task success and maintaining top quality criteria. By including these sophisticated technologies right into concrete scanning practices, building teams can improve process, lower task hold-ups, and ensure the total quality and success of the job.Offered the crucial nature of task efficiency and timelines in construction management, the focus currently changes towards making certain safety and mitigating dangers within the job setting.Concrete scanning plays a pivotal role in upholding top quality guarantee criteria within building and construction jobs. By using advanced scanning modern technologies such as Ground Passing Through Radar (GPR) and Concrete X-ray, task managers and designers can make sure the honesty and high quality of concrete structures.

Report this page